The versatile and flexible concept of the impingement oven is the right solution for most products and provides the baker with the optimal possibilities to adjust and optimize the baking profile fast and reliably for each product. The oven is equipped with multiple zones, and each zone consist of a number of 2m. long sections. The baking belt is chosen to suit the specific product’s process requirements.

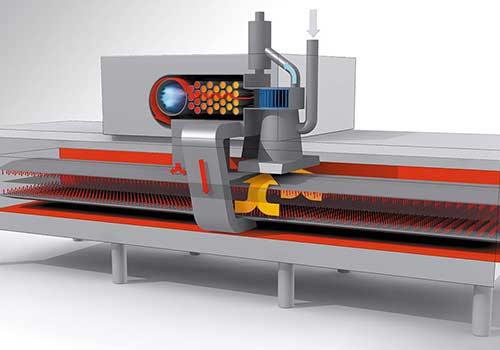

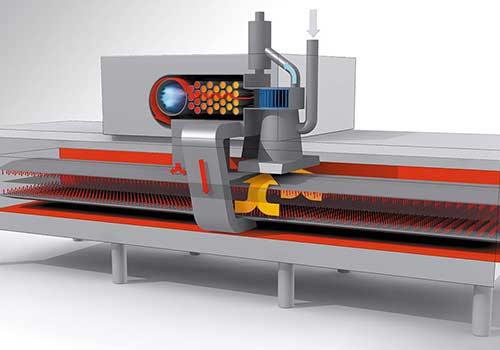

The working principle is indirect air impingement, an optimization of the well known convection principle. The heat from the gas burner is exchanged in the heat exchanger above the baking chamber. The baking air is not mixed with the combustion air. Direct Impingement ovens are also available, where combustion air is circulated in the baking chamber.

The direct gas fired (DGF) concept is usually chosen in the first part of the oven line to bake with more moisture and higher temperature in the first part of the baking process.

The working principle is gas ribbon burners fitted directly into the baking chamber. Various burner types makes it possible to make a unique baking profile for every product. The burner controls are split in top and bottom heat and in more zones.

A hybrid combination of the Direct Gas Fired oven and the Impingement Oven is desired by some bakeries, to bake their products to full perfection. The Direct Gas Fired concept is usually chosen in the first part of the oven line to bake with more moisture and higher temperature in the first part of the baking profile. The baking belt naturally runs through the entire oven length, and the oven controls takes care of the full baking line. To save energy for heating up the baking belt, the return belt can run through the lower part of the baking chamber.

This oven is a hybrid of the Direct Fired ribbon gas burners in the first zones and thereafter the well known convection principle, indirect or direct impingement air.

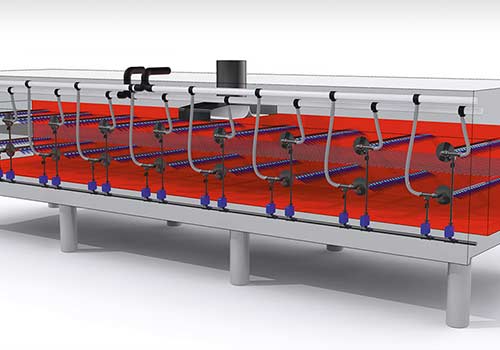

This modular cooling tunnel is cooled by a number of cooling towers on top of the cooling tunnel itself. The towers have high volume air fans, filters, cooling coils and water separation cell. The tunnel can be equipped with multiple zones, and each zone consist of a number of 2m long sections. The cooling belt can be any kind of plastic food approved belts or the baking belt can run straight through the tunnel.

Air is being circulated at high velocity through a large number of holes from either top or top and bottom. The air is cooled down through the cooling tower by cooling radiators using any cooling fluid. The calories from the products are sucked back to the cooling tower and re-cooled before returning into the tunnel.

There are various solutions to use for cooling down the products after the oven. Some products must be cooled down on the baking belt, before transferring the less fragile products to the next steps in the production line. Other products must be cooled more intensive in forced cooling tunnels in order to take as much heat out of the products before handling and packing.

Hydro baking band cooler by the use of cold water on the backside of the baking band.

Jet air cooler fan units is using the ambient air to blow away the evaporating heat from products. These can also be mounted on the underside of the baking band to remove heat from the band and thereby cooling the products.

Cooling tunnels are using forced air circulation at higher volumes and use a cooling fluid for the intensive cooling of the air.

With SENIUS’s highly experienced engineering staff we design and manufacture simple or very complex product loading and unloading systems. Retractors and oven loader conveyor units are reliable and innovative solutions to bakeries complex demands for reliable transport of the products.

SENIUS provides a special spreader machine, that through a dedicated design and function spreads a very even amount and structure of the granola or Müsli products. The hopper is top loaded and it can easily be rolled out for thorough cleaning of the product areas. For wider baking ovens an other spreading system is available, that uses a retractor belt for the even spread of products.

The circulated air in the baking chamber contains a variable amount of moisture. This amount is controlled by letting new fresh and dry air into the airflow. The amount of new fresh air is regulated by damper motors controlled by integrated humidity sensors.

Excessive warm air and combustion gasses are exhausted through the chimneys in each zone of the tunnel oven. A portion of this exessive heat can be recycled into the new fresh air for oven zone or to an external water system for cleaning etc.

Chimneys from each heat exchanger and the exhaust hoods can be supplied or the bakery can choose their own supplier.

Various solutions for cleaning the baking belt can be chosen; from single steel brush to scraper system and the combination of these.

Some products require baking on paper. SENIUS can install a paper applicator and paper roll-up system, that requires a minimum of operator activity.

Call sales on 03 9791 7011 to discuss SENIUS food equipment or fill in the call back form below and we'll get back to you.

Complete the form below and a member of our team will call you to discuss SENIUS food equipment.