| Model | EMULSYS 1000 |

| Size/Capacity |

- Effective Volume: 1,000 Lt

- Total Volume: 1,430 Lt |

| Overall dimensions | Length: 1500 mm Width: 2300 mm Height: 3340 mm |

| Stock number | COMP14460G |

| Serial number | G |

| Condition | Brand New |

Production ready

Backed by warranty

We supply our used machinery fully serviced, production ready and backed by warranty. This is included in our initial quotation.

Fully serviced

Production ready

Backed by warranty

We supply our used machinery fully serviced, production ready and backed by warranty. This is included in our initial quotation.

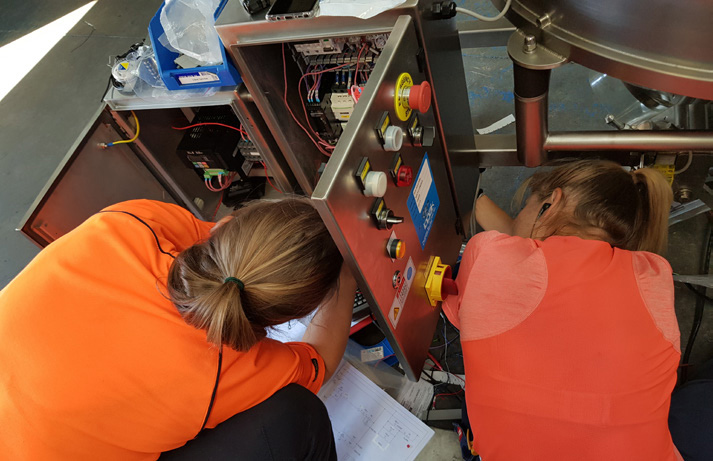

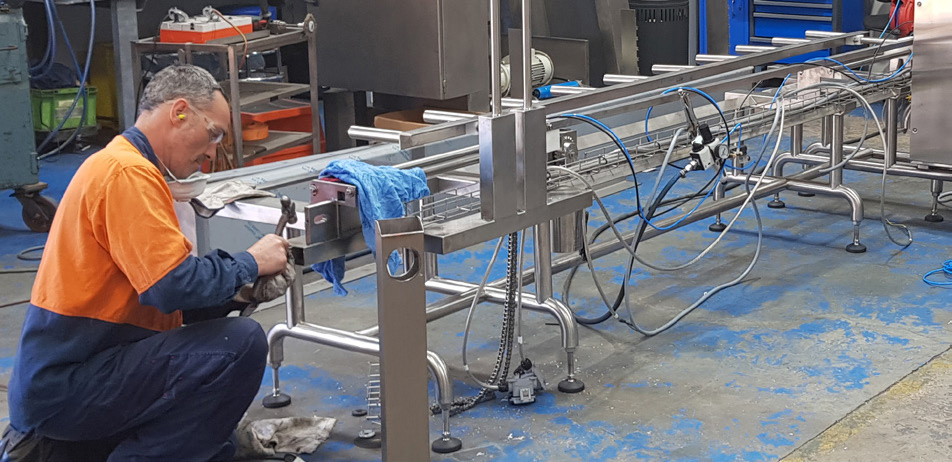

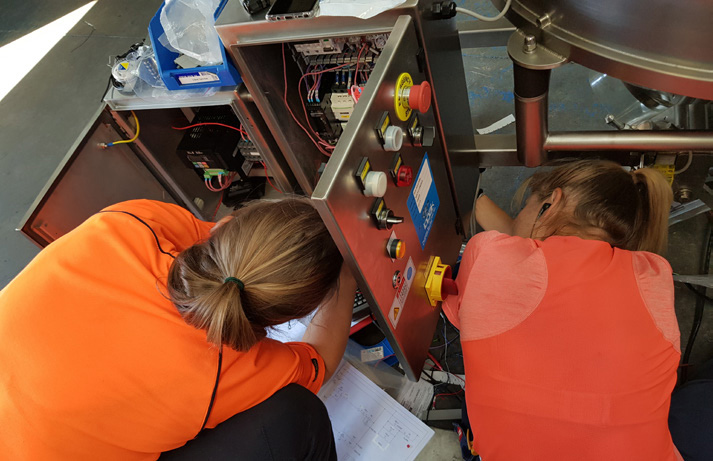

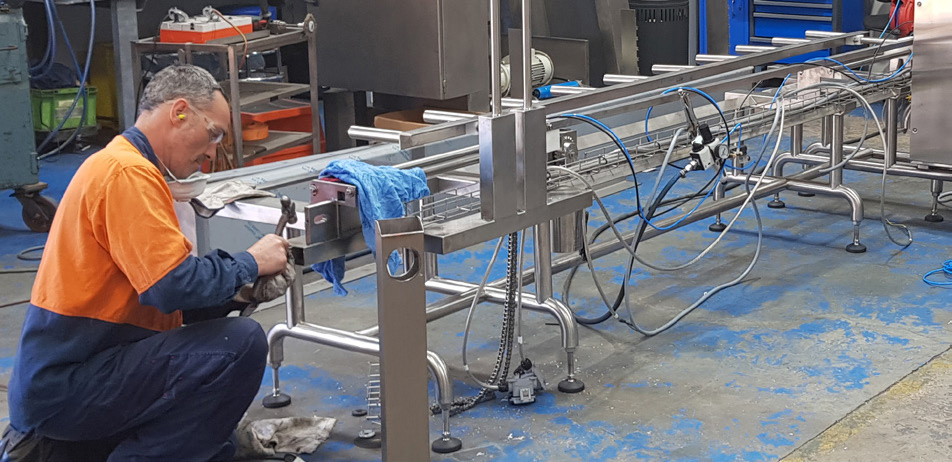

See your machinery running your product and/or packaging in our shop before it is delivered to your plant. You can be confident your machinery will be production ready after installation.

This allows you to see your system running and make those final critical changes that often make all the difference.

Our engineers are able to design your system to fit the floorplan of your plant, then build, configure and test it in our shop before delivering it plug-n-play on arrival.

Our engineers can train your staff in our shop, or we can arrange on-site commissioning and training (at additional cost).

We provide export crating, container loading and overseas freight services at additional cost.

For loose container load (LCL), we arrange an export crate using treated wood according to the machine size (to protect the machine from damage during transport) and crate the machine at our warehouse.

For full container load (FCL), we bring the empty container, load the equipment, and lash/secure them inside the container at our warehouse. We can then arrange either seafreight or airfreight to the customer's nominated destination sea/airports.

We usually arrange on the CFR (Cost and Freight) basis as per Incoterms.

Marine insurance, applicable local duties/taxes, custom clearance and delivery to customer's site in their destination country are to the customer's account.

We regularly provide this service for customers in New Zealand, the United Kingdom, the USA and Asia.

We will design a complete system based on your product, floor plan, budget and time frame. Our proposals include a summary quote and a scale engineering drawing.

Our engineers are able to design your system to fit the floorplan of your plant, then build, configure and test it in our shop before delivering it plug-n-play on arrival.

See your complete line running your product and/or packaging in our shop before it is delivered to your plant. This allows you to make those final critical changes that often make all the difference. You can be confident your machinery will be production ready after installation.

Our engineers can train your staff in our shop, or we can provide on-site commissioning and training.