| Model | FVR-8 -175 |

| Size/Capacity | 30 to 70 Packs/Minute |

| Overall dimensions | Length: 3240 mm Width: 2345 mm Height: 1650 mm |

| Weight | 1800 kg |

| Stock number | PVAC6170S |

| Serial number | 0710094 |

| Condition | Used |

| Year of manufacture | 1994 |

Production ready

Backed by warranty

We supply our used machinery fully serviced, production ready and backed by warranty. This is included in our initial quotation.

We will design a complete system based on your product, floor plan, budget and time frame. Our proposals include a summary quote and a scale engineering drawing.

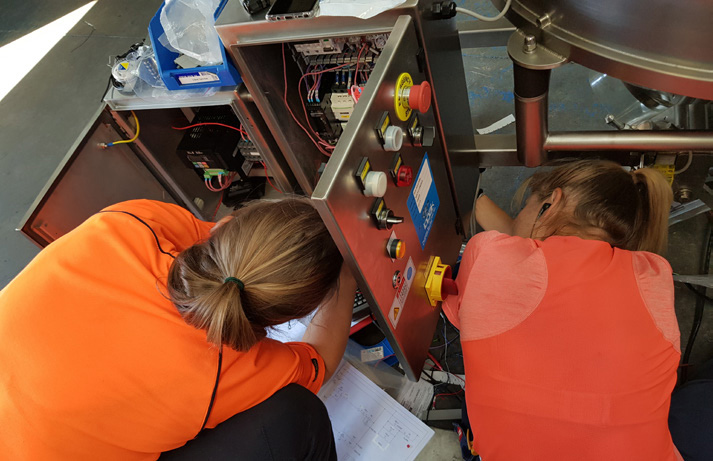

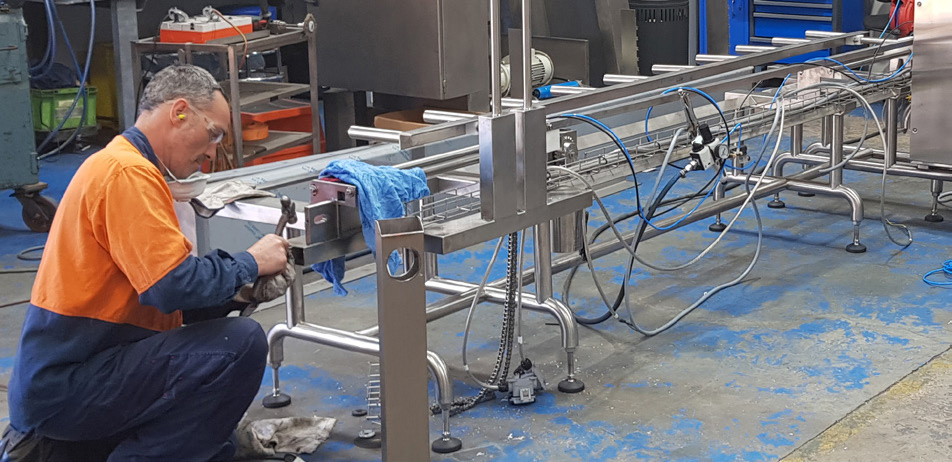

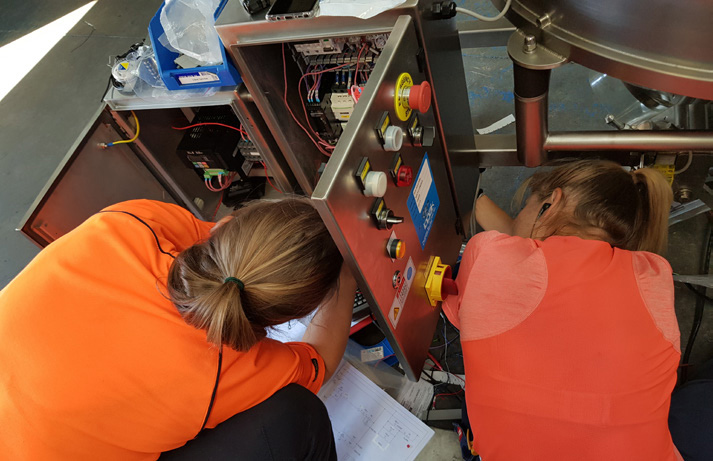

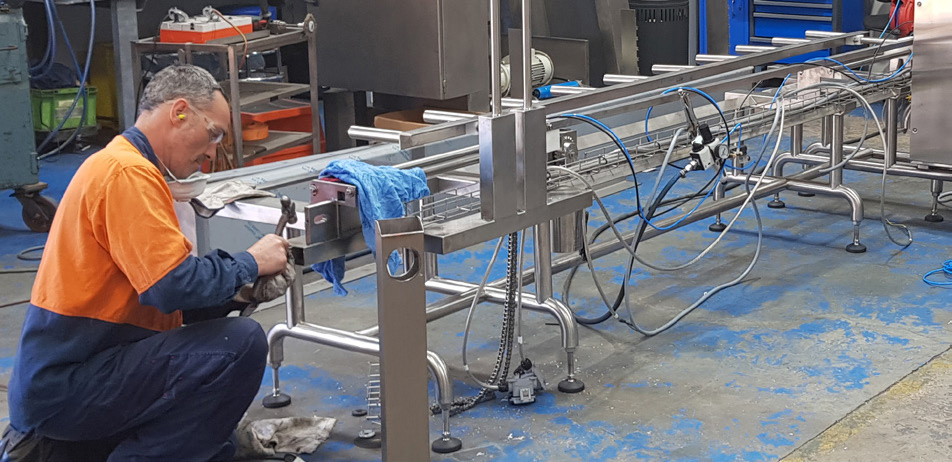

Our engineers are able to design your system to fit the floorplan of your plant, then build, configure and test it in our shop before delivering it plug-n-play on arrival.

See your complete line running your product and/or packaging in our shop before it is delivered to your plant. This allows you to make those final critical changes that often make all the difference. You can be confident your machinery will be production ready after installation.

Our engineers can train your staff in our shop, or we can provide on-site commissioning and training.